Aluminum T Channel: Types, Benefits & Where to Buy

Introduction: What Is an Aluminum T Channel?

Aluminum T channels are versatile structural components that have become indispensable across various industries, including construction, manufacturing, and DIY projects. These channels are characterized by their distinct 'T' shape, which provides a unique combination of strength and flexibility, making them ideal for a wide range of applications.

The basic structure of an aluminum T channel consists of a vertical web with a horizontal flange at the top, forming the shape of the letter 'T'. This configuration is particularly beneficial in industrial and structural applications where the distribution of weight and the ability to support loads are critical. The design allows for easy integration into existing frameworks, providing stability and support without adding excessive weight.

In construction, aluminum T channels are often used to create frameworks for buildings, offering a lightweight yet robust solution that can withstand environmental stresses. Their use extends to manufacturing, where they serve as components in machinery, contributing to modular designs that can be easily assembled and disassembled. For DIY enthusiasts, aluminum T channels offer a simple yet effective way to build custom furniture, shelving, and other home improvement projects.

The significance of aluminum T channels is further underscored by their material properties. Aluminum is known for its excellent corrosion resistance, making these channels suitable for both indoor and outdoor applications. Additionally, the high strength-to-weight ratio of aluminum ensures that these channels provide the necessary support without compromising on mobility or ease of installation.

Overall, the aluminum T channel is a critical component in many sectors, offering solutions that meet both structural and aesthetic requirements. Whether used in large-scale industrial projects or small DIY tasks, these channels demonstrate the versatility and efficiency that aluminum brings to modern engineering and design.

Types of Aluminum T Channels and Their Variations

When it comes to aluminum T channels, variety is a key feature that caters to different industrial, construction, and DIY needs. Understanding the types and variations of these channels can help you choose the right configuration for your specific application.

T Channel Aluminum: Standard Configurations

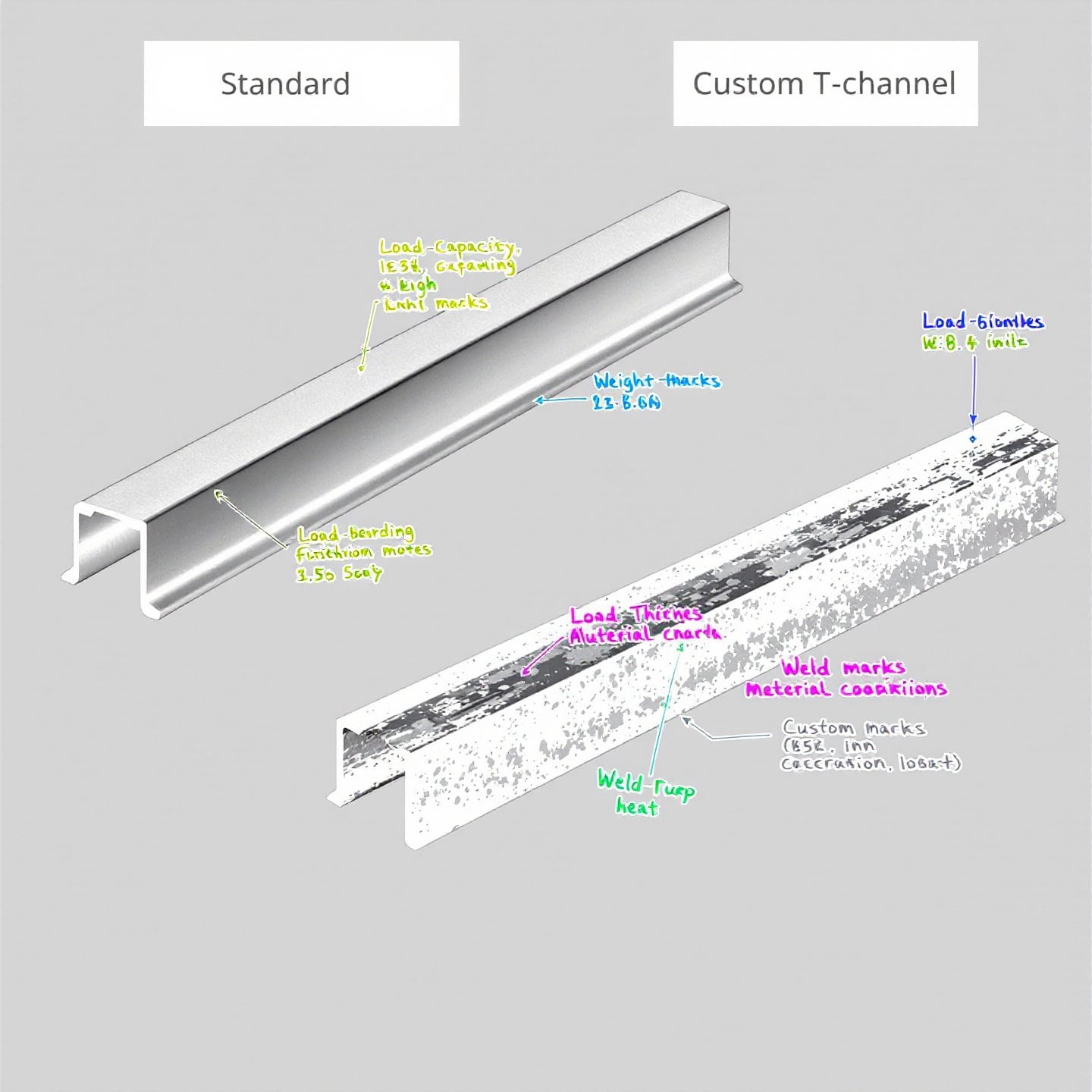

The standard T channel aluminum comes in various sizes and thicknesses, designed to meet diverse structural requirements. These channels are typically used in applications where a strong, lightweight support is needed, such as in frameworks for buildings or as components in machinery. The standard T channel provides a straightforward solution for distributing weight evenly across structures, ensuring stability and support.

Aluminum T Channel Extrusion: Customization and Flexibility

Extruded aluminum T channels are created through a process that forces aluminum through a die to achieve the desired shape. This method allows for high precision and customization, making it possible to produce channels that meet specific design requirements. According to Wellste , their extruded T channels are not only durable and lightweight but also available in a wide range of finishes and colors. This customization extends to the ability to cut, drill, or bend the channels to fit unique project needs, offering unparalleled flexibility for designers and engineers.

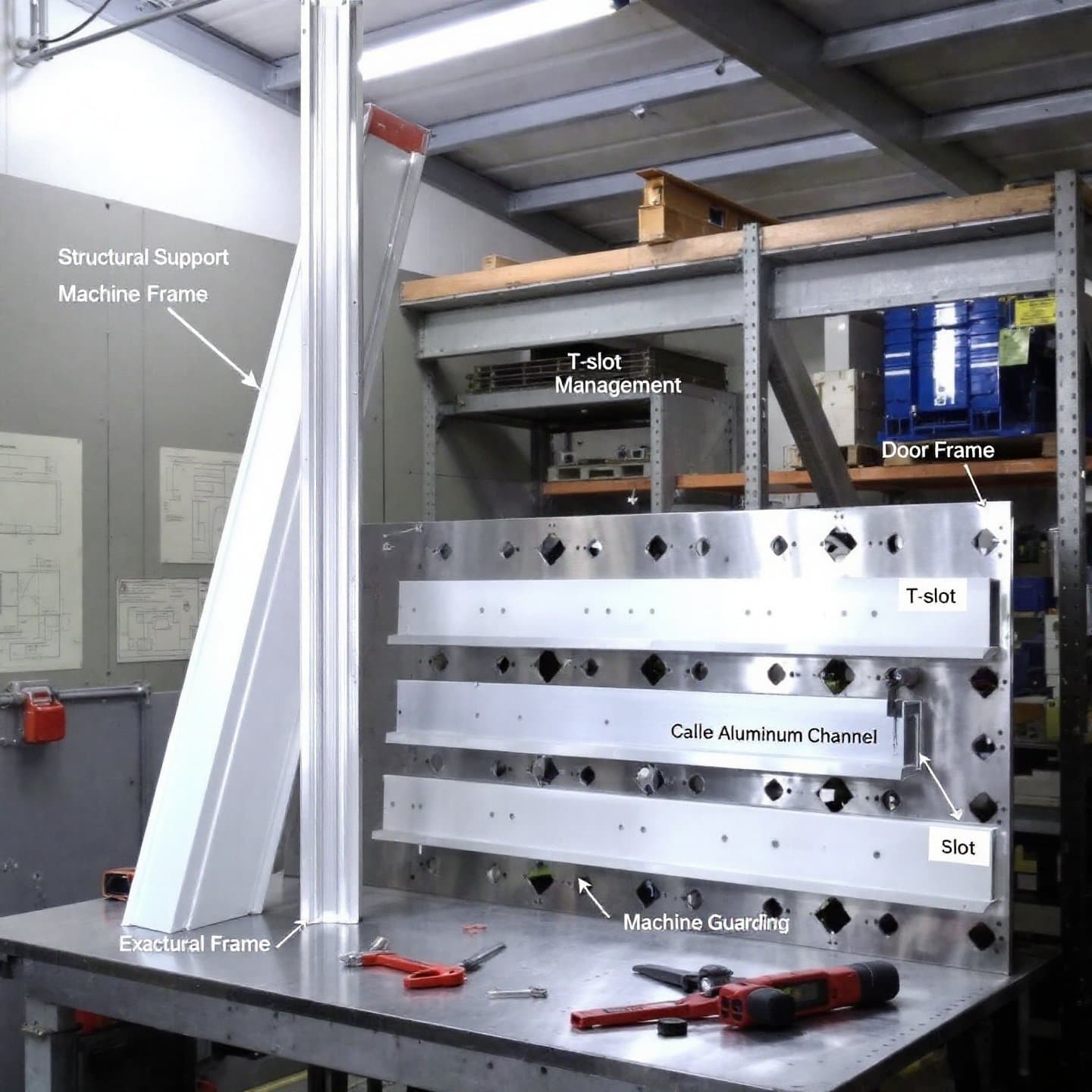

T Slot Aluminum Channel: Versatility in Design

The T slot aluminum channel is a popular choice for projects requiring modular and adjustable frameworks. These channels feature a T-shaped slot along their length, allowing for easy attachment of various components and hardware. As highlighted by Gabrian International , T slot channels are ideal for creating custom structures like machinery enclosures, workbenches, and even complex automation systems. Their design facilitates quick assembly and disassembly, making them a practical choice for projects that require frequent modifications or relocations.

In conclusion, the diversity of aluminum T channels—from standard to extruded and T slot variations—provides solutions for a wide array of applications. Whether you need a simple structural support or a complex, customizable framework, there's an aluminum T channel designed to meet your needs. Next, we'll delve into the manufacturing processes that make these versatile components possible.

How Aluminum T Channels Are Manufactured: The Extrusion Process

The production of aluminum T channels is a fascinating process primarily involving extrusion, a method that allows for the creation of complex cross-sectional profiles with high precision. This process is essential for producing the versatile extruded aluminum T channel, widely used in various industries due to its adaptability and strength.

Understanding the Aluminum Extrusion Process

Extrusion involves forcing heated aluminum alloy through a die that shapes the material into the desired profile. Imagine squeezing toothpaste through a tube; similarly, the aluminum emerges from the die in a continuous profile, which can be cut to specific lengths. This process not only ensures uniformity but also allows for the creation of both simple and intricate shapes, including solid, hollow, and semi-hollow profiles. According to Gabrian International , the extrusion process results in profiles that can be further enhanced through heat treatment and finishing operations.

Benefits of Extrusion for Custom Shapes

One of the primary benefits of using the extrusion process for aluminum T channels is the ability to customize shapes to meet specific design needs. Whether standard or custom, extruded aluminum T channels can be tailored to precise specifications, ensuring they fit seamlessly into any project. This customization is particularly advantageous in industries where specific dimensions and profiles are critical for functionality and aesthetics. The process allows for the production of extruded aluminum channel T-slot profiles, which are popular for their modularity and ease of assembly.

Precision and Flexibility in Various Industries

The precision and flexibility offered by the extrusion process make extruded aluminum T channels an ideal choice for a wide range of applications. Industries such as construction, automotive, and aerospace rely on these channels for their structural components, as they offer the perfect balance of strength and weight. The ability to produce channels with exact dimensions and finishes means they can be used in both visible and hidden applications, providing both functional and aesthetic benefits.

Moreover, the extrusion process allows for additional fabrication operations, such as drilling, cutting, and machining, to achieve the final dimensions required for a project. This flexibility ensures that extruded aluminum T channels can be adapted to meet the evolving needs of any industry, making them a cornerstone of modern engineering solutions.

In summary, the extrusion process is key to the versatility and effectiveness of aluminum T channels. By offering precision, customization, and flexibility, it enables the production of components that meet the exacting demands of various sectors. As we continue, we'll explore the diverse applications of these channels across different industries.

Applications of Aluminum T Channels in Industry

Aluminum T channels are integral to numerous industries due to their unique combination of strength, lightweight properties, and versatility. Their applications span from large-scale construction projects to intricate DIY endeavors, showcasing their adaptability across different sectors.

Structural Applications: Building Frameworks and Support Systems

In the construction industry, aluminum T channels play a crucial role in creating robust frameworks for buildings. Their high strength-to-weight ratio makes them ideal for use in structural applications such as building frames, shelving, and support beams. These channels offer the necessary support without adding significant weight, which is particularly beneficial in high-rise buildings and structures exposed to environmental stresses. Furthermore, their corrosion resistance ensures longevity and durability, even in harsh outdoor environments.

Machinery & Automation: Enhancing Modular Designs

The use of aluminum T channels extends into the realm of machinery and automation, where they contribute to the creation of strong, modular structures. These channels are often used in the assembly of machinery frames and enclosures, providing a flexible yet sturdy framework that can be easily adjusted or expanded as needed. According to Industrial Metal Supply , their adaptability makes them an excellent choice for custom machine parts and components, allowing for quick reconfiguration and easy maintenance.

DIY Projects: Versatility for Home Improvements

For DIY enthusiasts, aluminum T channels open up a world of possibilities in home construction and improvement projects. Whether building custom furniture, crafting unique shelving units, or creating frames for home decor, these channels provide a simple yet effective solution. As highlighted by Otalum , their ease of use and adaptability make them a favorite among hobbyists looking to enhance their projects with precision and efficiency. The T slot channel aluminum design, in particular, allows for easy attachment of various accessories, making it a versatile addition to any DIY toolkit.

In summary, the applications of aluminum T channels are vast and varied, reflecting their importance in both industrial and personal projects. Their ability to provide structural integrity, facilitate modular designs, and enhance DIY projects underscores their value across different fields. As we move forward, understanding the benefits of these channels will further highlight why they are a preferred choice in many applications.

Understanding the Benefits of Aluminum T Channels

Aluminum T channels offer a range of benefits that make them a preferred choice over other materials and channel types. Their unique properties provide distinct advantages in terms of durability, versatility, and cost-effectiveness, making them indispensable across various sectors.

Durability and Strength: A High Strength-to-Weight Ratio

One of the most significant benefits of aluminum T channels is their impressive strength-to-weight ratio. This property allows them to provide robust support without contributing excessive weight to structures. Unlike heavier metals, aluminum maintains its strength under various conditions, making it ideal for applications where both strength and lightness are crucial. Furthermore, aluminum's natural corrosion resistance ensures that T channels remain durable even in harsh environments, reducing the need for frequent replacements or repairs.

Versatility: Adaptability Across Industries

The versatility of aluminum T channels is another reason for their widespread use. They can be easily customized through processes like aluminum T channel extrusion, which allows them to be tailored to specific project requirements. This adaptability makes them suitable for a variety of applications, from constructing building frameworks to assembling machinery components. Their ability to be easily cut, drilled, and assembled without specialized tools further enhances their utility across different sectors, including construction, automotive, and aerospace industries.

Cost-Effectiveness: Long-Term Savings

In addition to their physical benefits, aluminum T channels offer significant cost advantages. Their durability reduces maintenance costs, and their lightweight nature can lower transportation expenses. Moreover, aluminum's recyclability contributes to long-term savings and environmental sustainability, as it can be reused without losing its intrinsic properties. This makes aluminum T channels not only a practical choice but also an economically sound one, particularly in large-scale projects where budget considerations are crucial.

In summary, the benefits of aluminum T channels—spanning durability, versatility, and cost-effectiveness—underscore their value in modern engineering and construction. As we continue to explore these channels, understanding how to select the right one for your specific application will be our next focus.

Choosing the Right Aluminum T Channel for Your Project

Selecting the appropriate aluminum T channel for your project can significantly influence the outcome, ensuring both functionality and efficiency. Whether you're embarking on a construction endeavor or a DIY project, understanding the key factors in choosing the right T channel is essential.

Factors to Consider

- Load-Bearing Capacity: One of the first considerations is the load the T channel needs to support. Evaluate the weight and stress levels the channel will encounter to ensure it provides adequate support without bending or breaking.

- Environmental Conditions: Consider the environment where the T channel will be used. For outdoor applications, opt for channels that offer corrosion resistance, such as those made from aluminum alloys like 6061 or 6063, which are known for their durability and resilience.

- Dimensions: The length, width, and wall thickness are critical. These dimensions should align with your specific requirements, whether you're looking for a standard size or need a custom cut. Sites like Online Metals offer a variety of dimensions to choose from.

Custom vs. Standard T Channels

When deciding between custom and standard T channels, consider the complexity and specificity of your project. Standard channels are cost-effective and readily available, making them suitable for straightforward applications. However, if your project demands unique specifications or a particular aesthetic, custom T channels offer the flexibility to meet those needs. Custom channels can be tailored in terms of size, shape, and finish, providing a precise fit for complex projects.

Where to Source Aluminum T Channels

Once you've determined the type of T channel you need, the next step is sourcing it. Retailers like Home Depot are excellent for purchasing standard aluminum T channels due to their wide availability and competitive pricing. For more specialized needs, consider suppliers that offer custom extrusion services or a broader range of dimensions, such as those found online. Evaluating the supplier's reputation, product quality, and customer service is crucial to ensuring you receive a reliable product that meets your project's demands.

In conclusion, selecting the right aluminum T channel involves careful consideration of several factors, from load-bearing capacity to sourcing options. By understanding these elements, you can ensure your project benefits from the structural integrity and versatility that aluminum T channels provide. Next, we'll explore the best places to purchase these channels and what to look for in a supplier.

Where to Buy Aluminum T Channels: Popular Sources and Suppliers

Finding the right supplier for aluminum T channels is crucial to ensuring you receive a product that meets your project’s requirements. Whether you're looking to buy aluminum T channels for industrial use or a personal DIY project, understanding where to purchase them and what to consider can make a significant difference in the quality and suitability of the channels you acquire.

Online Stores vs. Local Suppliers

When it comes to sourcing aluminum T channels, both online stores and local suppliers offer unique advantages. Online platforms such as Amazon and specialized metal suppliers like Online Metals provide a wide range of options, often with detailed product specifications and customer reviews. This can be particularly useful when searching for specific dimensions or custom finishes. Online shopping also allows for easy price comparisons across different sellers, helping you find competitive pricing.

Local suppliers, including large retailers like Home Depot, offer the benefit of immediate availability and the opportunity to physically inspect the product before purchase. This can be advantageous if you need the channels quickly or prefer to verify the material's quality firsthand. Additionally, local suppliers often provide personalized customer service, which can be helpful if you require guidance on selecting the right product for your application.

Evaluating the Quality of Aluminum T Channels

Regardless of where you choose to buy, assessing the quality of aluminum T channels is essential. Here are some tips to help you evaluate potential purchases:

- Material Specifications: Check the alloy type and temper designation to ensure it meets your project’s strength and corrosion resistance requirements. Common alloys like 6061 and 6063 are known for their excellent mechanical properties and durability.

- Finish and Coating: Consider the finish of the T channels, especially if they will be visible in your project. Options include anodized, powder-coated, or mill finish, each offering different levels of protection and aesthetic appeal.

- Supplier Reputation: Research the supplier's reputation through customer reviews and ratings. Reliable suppliers often provide guarantees or warranties, ensuring you receive a high-quality product.

- Certifications: Look for certifications or compliance with industry standards, which can be an indicator of quality and reliability.

By carefully selecting your supplier and evaluating the quality of the aluminum T channels, you can ensure that your purchase will meet the demands of your project, both in terms of performance and longevity. As we conclude, understanding the importance of these considerations will help you make informed decisions, ensuring the success of your construction or DIY endeavors.

Conclusion: The Future and Benefits of Aluminum T Channels

Aluminum T channels have established themselves as a cornerstone in construction and industrial applications, thanks to their remarkable benefits. Their high strength-to-weight ratio, corrosion resistance, and adaptability make them an invaluable component in projects ranging from skyscrapers to intricate machinery. These channels not only provide structural integrity but also offer cost-effectiveness through reduced maintenance and energy savings.

Looking ahead, the future of aluminum T channels is promising, with advancements in extrusion technology paving the way for more sustainable and precise applications. As industries increasingly demand lightweight and sustainable materials, innovations such as precision extrusion and recycling will play pivotal roles. These developments will enhance the efficiency and environmental footprint of aluminum T channels, ensuring they remain at the forefront of modern engineering and construction.

Suqian Sunmay Aluminium stands out in this evolving landscape, offering a diverse range of high-quality aluminum profiles tailored to meet global standards. With cutting-edge technology and a commitment to customer satisfaction, Sunmay provides solutions that align with the latest trends in aluminum extrusion. Their expertise in crafting custom profiles and implementing advanced surface treatments ensures that their products meet the highest expectations in both performance and aesthetics. For more information on their offerings, visit Sunmay's official website .

In conclusion, aluminum T channels continue to be a vital resource across various sectors, with their benefits and future potential making them an essential element in construction and industrial innovation. By choosing the right supplier and staying informed about industry trends, businesses and DIY enthusiasts alike can harness the full potential of these versatile components.

Frequently Asked Questions

1. What is T-slot aluminum used for?

T-slot aluminum is widely used in industrial settings for building workstations, machine frames, conveyors, and safety guards due to its modularity and adaptability.

2. How strong is an aluminum T-slot?

Aluminum T-slots offer impressive strength with a tensile strength of up to 38,000 psi and are capable of supporting significant loads, making them ideal for robust structural applications.

3. What are the benefits of using aluminum T channels?

Aluminum T channels provide a high strength-to-weight ratio, corrosion resistance, and cost-effectiveness, making them suitable for diverse structural and industrial applications.

4. How are aluminum T channels manufactured?

Aluminum T channels are primarily manufactured through the extrusion process, which allows for precise and customizable shapes suitable for various industrial needs.

5. Where can I buy aluminum T channels?

Aluminum T channels can be purchased from online retailers like Amazon and Online Metals, or from local suppliers such as Sunmay Aluminum, offering a range of sizes and finishes.

- Aluminum T Channel: Types, Benefits & Where to Buy

- Introduction: What Is an Aluminum T Channel?

- Types of Aluminum T Channels and Their Variations

- How Aluminum T Channels Are Manufactured: The Extrusion Process

- Applications of Aluminum T Channels in Industry

- Understanding the Benefits of Aluminum T Channels

- Choosing the Right Aluminum T Channel for Your Project

- Where to Buy Aluminum T Channels: Popular Sources and Suppliers

- Conclusion: The Future and Benefits of Aluminum T Channels

- Frequently Asked Questions